9-roller Metal Sheet Straightening Machine Plate Leveling Machine for 20mm thickness plate

1. Application scope:

This plate straightening machine is applicable for fine leveling of normal/medium plate, high-precision and high-strength plates, suitable for both steel and stainless steel plates.

2. Technical Parameters:

| Machine type | 9-roller plate straightening machine |

| Model No. | HQW43-20x3000 |

| Maximum plate thickness | 20 mm |

| Minimum plate thickness | 5 mm |

| Maximum plate width | 3000 mm |

| Plate yield limit | 245 MPa, 345 MPa or as per required |

| Plate Leveling speed | 2~7 m/min adjusable |

| Number of Work rolls | 9 pcs |

| Work roll layout | Upper with 4 rolls and Lower with 5 rolls |

| Work roll diameter | 200 mm |

| Roll spacing | 220 mm |

| Number of Support rolls | 2 columns (total 22 rolls) |

| Downpress stroke | 70 mm (-10 mm ~ +60 mm) |

| Downpress speed | Approx.35 mm/min |

| Leveling accuracy | Not more than 1 mm/m |

(*Above parameters are indicative and can be modified as per customers's actual requirements.)

3. Machine Features:

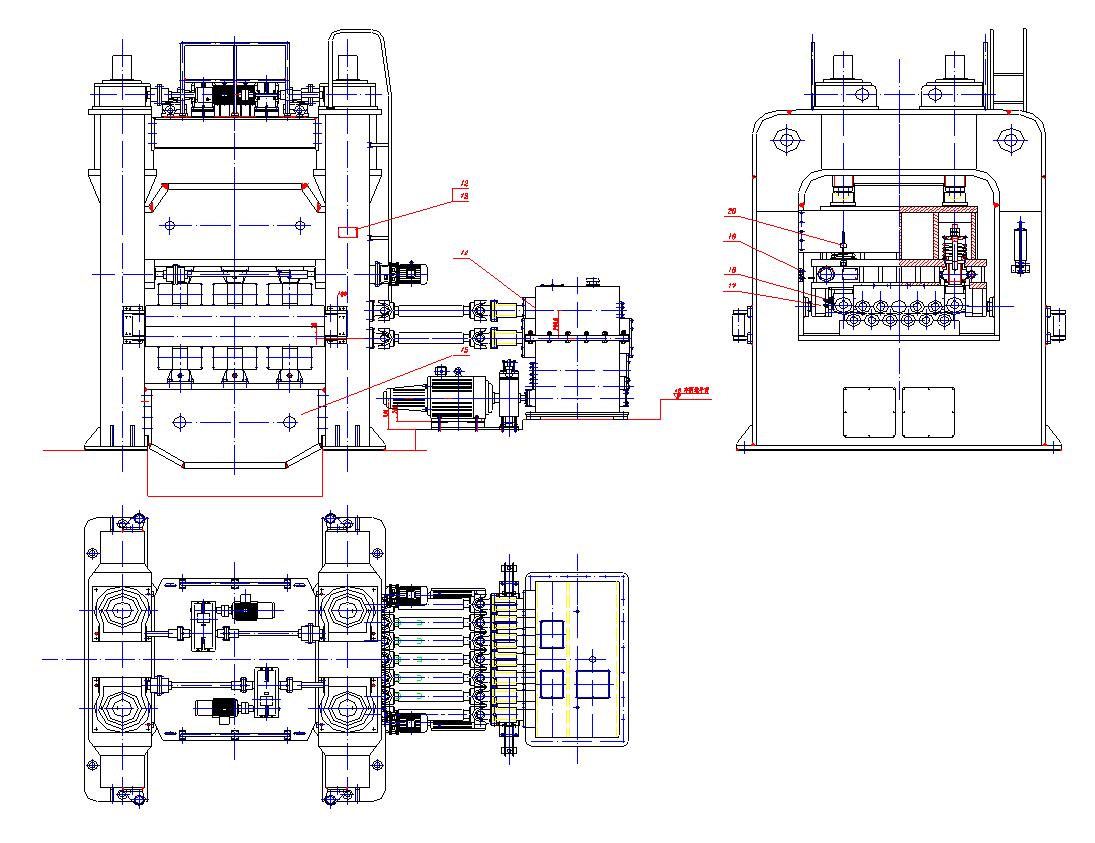

1) The machine is a mechanical type. It consists of machine frame,movable crossbeam, lower cross beam, mani transmission device, work roll assembly, support roll assembly, downpress mechanism, balance device, guide rolls and electrical control system etc.

2) It's suitable for the leveling of medium plate, high-precision and high strength plate.

3) Need multiple reciprocating leveling for thin plates.

4) Overall steel welding frame structure, carried out stress annealing relief treatment after welding. The frame structure with high strength and rigidity.

5) The main machine is equipped with side vertical roller to limit the deviation of steel plate during conveying.

6) The work rolls and support rolls are all carried out surface hardening treatment and flaw detection.

7) All the roll bearings are self-aligning roller bearings.

8) With Automatic feeding and discharging roller table to facilitate the feeding and exiting of the straightening machine. The feeding roller table is equipped with a plate centering device and the rollers are powered.

9) The sheets to be levelled can feed from both sides, and leveled repeatly.

10) It's suitable for the leveling of medium plate, high-precision and high strength plates.

11) Digital display, PLC control. Visual input, edit, modify and store process parameters.

12) Siemens PLC, Balluff Displacement transducer.

4. Other Model for Optional:

Model No. | Max Leveling thickness (mm) | Min Leveling thickness (mm) | Max Leveling width (mm) | Plate yield limit (Mpa) | Work roll diameter (mm) | Work roll qty | Main motor power (kW) | Overall size (m) |

HQW43-140x4000 | 140 | 40 | 4000 | 240 | 680 | 7 | 2x200 | 19.2x7.2x13.6 |

HQW43-120x4000 | 120 | 30 | 4000 | 240 | 660 | 7 | 2x200 | 18.6x6.6x12.2 |

HQW43-80x4000 | 80 | 25 | 4000 | 800 | 680 | 7 | 2x450 | 19.88x7x13.2 |

HQW43-60x4000 | 60 | 16 | 4000 | 240 | 420 | 7 | 2x110 | 14.8x3.8x7.5 |

HQW43-32x3150 | 32 | 10 | 3150 | 800 | 370 | 7 | 2x300 | 13.7x3.4x7.2 |

HQW43-22x2200 | 22 | 5.5 | 2200 | 1500 | 340 | 9 | 2x180 | 12.1x3.2x6.9 |

HQW43-16x2000 | 16 | 5 | 2000 | 1500 | 280 | 9 | 2x160 | 11.2x3.0x5.9 |

HQW43-12x2500 | 12 | 4 | 2500 | 960 | 200 | 11 | 90 | 11.2x2.4x5.8 |

(*Above parameters are indicative and can be modified as per customers's actual requirements.)