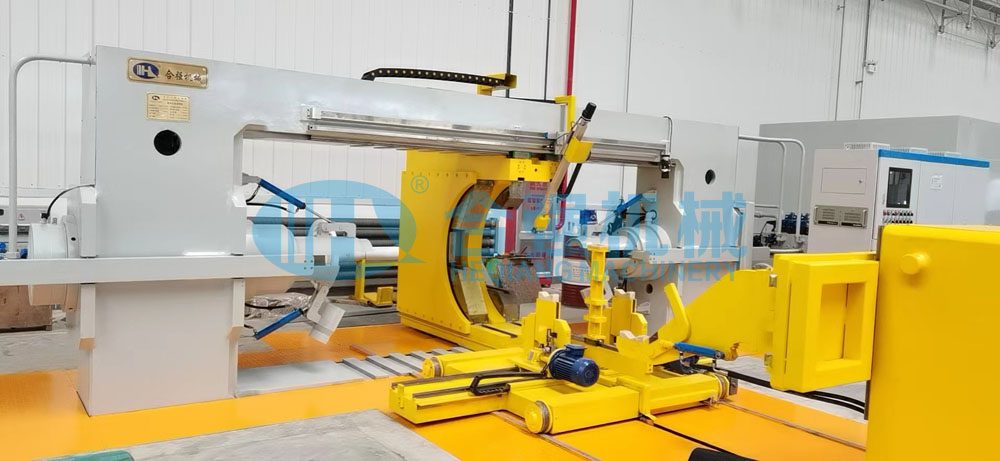

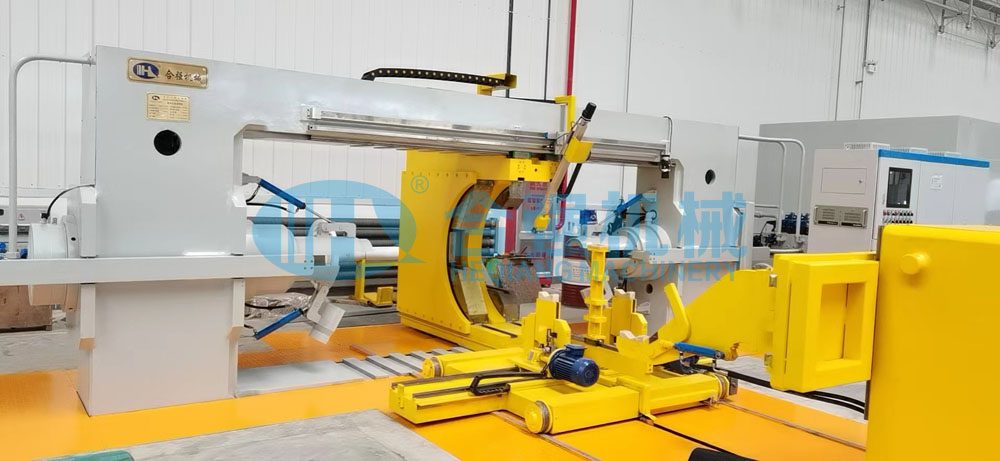

Horizontal Hydraulic Wheelset Press, Wheelset Mounting and Dismounting Press

Application scope:

This horizontal wheel press is a fully automatic design. It's used to mount, dismount and back-pressure test the wheels and brake discs safely and effectively for railway metro, intercity vehicles and high-speed trains. With pre-fitting stand. With measurement and curve recording system.

This hydraulic wheel press is applicable for the wheelset with bearings at inner side of wheels.

2) Only one operator required to operate the wheel press.

3) Gantry frame structure, with high strength, good rigidity and less deformation.

4) Double-end cylinder pressing.

5) Unique Invention patented cylindrical ram for wheel mounting, with high pressing accuracy.

6) Only need one positioning to proceed the 2 wheels' mounting and dismounting without reversal of the axle.

7) Special patented centring devices at both ends of two ram cylinders for center hole positioning. The centre can insert into the center hole of both ends of the axle for wheelset positioning.

8) The centre devices only bear the weight of the axle and do not bear the large pressure of the oil cylinder.

9) Movable slider device with replaceable inserts to block the wheels, gears or brake discs for dismounting.

10) An electrical support trolley is provided for loading/unloading onto/off from the press.

11) With a pre-fitting stand for wheelset preassembly.

12) Siemens S7-300 PLC and AdvanTech industrial computer to control the operation.

13) The press can track and control the whole process, detect the pressing condition of the wheelset, and analyze and process it through industrial computer. It can export the pressure vs displacement curve and other results onto the screen and printer.

Application scope:

This horizontal wheel press is a fully automatic design. It's used to mount, dismount and back-pressure test the wheels and brake discs safely and effectively for railway metro, intercity vehicles and high-speed trains. With pre-fitting stand. With measurement and curve recording system.

This hydraulic wheel press is applicable for the wheelset with bearings at inner side of wheels.

Technical parameters:

| Maximum pressing force | 300 tons |

| Number of cylindrical ram | 2 pcs (1 left + 1 right) |

| Number of Ram cylinder | 2 pcs (1 left + 1 right) |

| Piston stroke | 600 mm |

| Rapid approach and return speed | 25 mm/s |

| Pressing speed | 0~5 mm/s |

| Number of wheelset support trolley | 1 set |

| Max trolley load | 3000 kg |

Maximum Hydraulic system pressure | 31.5 MPa |

| Total installed power | ≤ 30 kW |

| Pressure sensor accuracy | 0.25% FS |

| Displacement sensor accuracy | ± 0.01 mm |

| Inner distance control accuracy | ≤ ± 0.5 mm |

| Wheel position difference control accuracy | ≤ ± 0.5 mm |

| Maximum wheelset weight | 3000 kg |

| Axle length | 1600 ~ 2600 mm |

| Wheel diameter | Φ650 ~ Φ920 mm |

| Wheel seat diameter | Φ130 ~ Φ230 mm |

(*Remarks: The above parameters are indicative and can be modified as per customer's actual requirements.)

Machine Features:

2) Only one operator required to operate the wheel press.

3) Gantry frame structure, with high strength, good rigidity and less deformation.

4) Double-end cylinder pressing.

5) Unique Invention patented cylindrical ram for wheel mounting, with high pressing accuracy.

6) Only need one positioning to proceed the 2 wheels' mounting and dismounting without reversal of the axle.

7) Special patented centring devices at both ends of two ram cylinders for center hole positioning. The centre can insert into the center hole of both ends of the axle for wheelset positioning.

8) The centre devices only bear the weight of the axle and do not bear the large pressure of the oil cylinder.

9) Movable slider device with replaceable inserts to block the wheels, gears or brake discs for dismounting.

10) An electrical support trolley is provided for loading/unloading onto/off from the press.

11) With a pre-fitting stand for wheelset preassembly.

12) Siemens S7-300 PLC and AdvanTech industrial computer to control the operation.

13) The press can track and control the whole process, detect the pressing condition of the wheelset, and analyze and process it through industrial computer. It can export the pressure vs displacement curve and other results onto the screen and printer.